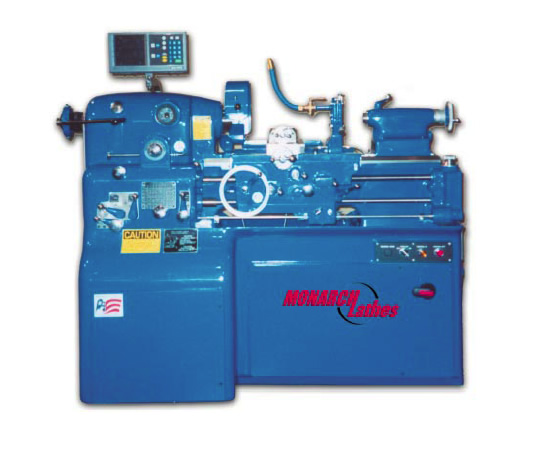

Monarch EE Series

Monarch’s reputation for excellence is clearly reflected in the Model EE 10” Precision Toolmaker’s Lathe; a tool so precise, sensitive and durable that it has become the standard to which all others are compared.

The EE is built to work hard, year after year, turning out work with virtually the same precision as the day it started.

In fact, many EE lathes are used for years in precision production work. That stamina is what really determines the profitability of any precision machine.

A brief overview of the EE clearly shows why it’s worth more to you by design.

- Responsive ac inverter solid state spindle drive

- Exact speed control under all operating conditions

- Full English/Metric combination available

- End gear train used only for precision thread chasing

- Anti-friction bearings used in all critical areas. All sliding movements are smooth and effortless

- Precision gears

- Lead screw, cross feed screw and compound screw all induction hardened and ground

- Heat treated alloy steel used in all critical parts

- Metallurgically controlled alloy cast iron bed and base

- Flame hardened, precision ground ways

- Smooth, vibrationless multiple V-belt drive

- Self-aligning ball bearing gibs

- Automatic lubrication

- Massive cast iron base with three point suspension

12-1/2” (315mm) swing over bedways Thread chasing stop 7-1/4” (180mm) swing over cross slide Thread chasing dial 20” (505mm) or 30” (705mm) center distance Chuck shield English/Metric gearbox Necessary wrenches Electrical leadscrew reverse Combination English/Metric dials on crossfeed, compound and tailstock Interchangeable English/Metric dial indicators for carriage stop Spindle speed range 25-4000 RPM Hardened ASA 3” - D-1 camlock spindle nose with 1-13/32” (35mm) hole through spindle Quick clamping tailstock with dead center spindle - #2 Morse Taper One set Monarch manuals and support documentation Compound rest and dials Complete with all electrical controls mounted & wired. Arranged for AC 230 or 460 volts, 3 phase, 60 Hz (customer must specify) power supply. Customer voltage to machine must be regulated within + 10%. 7-1/2HP (5.6Kw) AC variable speed solid state spindle drive with electronics mounted in machine base and 5 to 1 gear reducer on motor for low speeds Attachment Size Monarch-EE-Series.pdf 127.68 KB